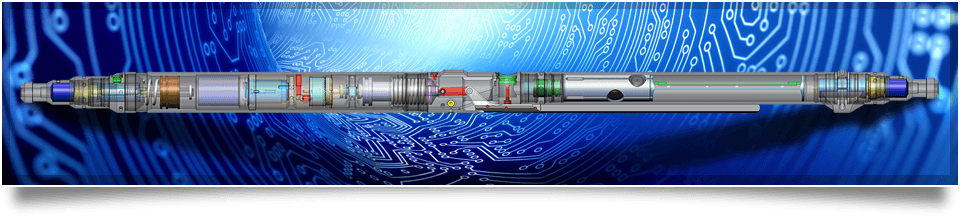

Primary Circuit Board Assembly

Primary Sourcing has over 15 years of experience with Printed Circuit Board Assembly (PCBA). We specialize in demanding turn-key requirements of high-mix down-hole technology for oilfield equipment and service companies. Our stable and technically competent workforce specializes in mission critical products where the cost of failure can far exceed the cost of the equipment.

Our Printed Circuit Board Assembly Capabilities includes:

- General

- Selection of FR4, Polyimide and Flex Circuits material’s on both Single and Double-Sided PCB’s

- Fully controlled ESD facility including Material Stockroom

- Highly experienced and trained staff. Average 15-20 years’ experience on J-Std-001 and IPC Class 3 standards

- Use of 40x microscopes during Soldering and Inspection process

- IPC-A-610A Class 3 Workmanship Standards

- Surface Mount and Through-Hole Technology

- Low Temp Solder Types – Sn63/Pb37 and SN96

- High Temp Solder Types – Pb85, HMP and Gold

- Dek Automated Solder Paste Printer

- Multi Surface Mount Devices (SMD) placer – 0201, QFP’s and BGA’s

- Heller 13 zone High-Temperature reflow with Nitrogen capabilities

- KIC2000 Temperature profiling verification kit and process

- Mirtech Automated Optical Inspection

- Offline processes

- Dedicated Prep and Tinning process group

- Vapor Degreaser Cleaning process

- Semi-automated depaneling machine

- Press-fit capabilities

- Conformal coating, Encapsulation, Staking and Potting

For more information on our full range of services, please call 713-952-5405 or use our contact form.